Automation: The Heart of Smart Manufacturing

Did you know that over 50% of manufacturers are now using automation in their processes? This trend is changing the game for industries everywhere. Automation is not just a fancy term; it’s a powerful tool shaping the future of manufacturing. Lets dive into why automation is the heart of smart manufacturing and how it can benefit businesses and consumers alike.

What is Smart Manufacturing?

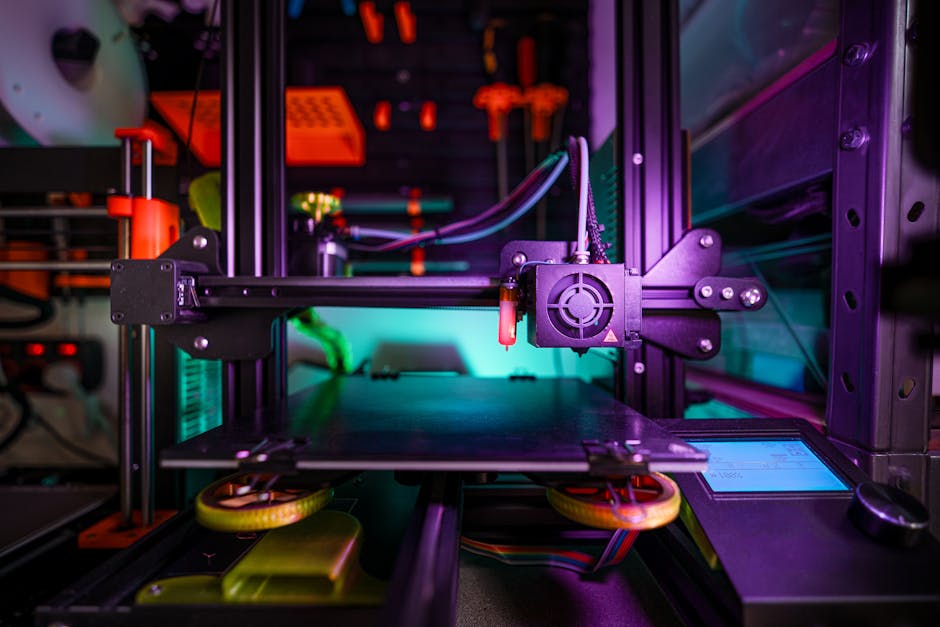

Smart manufacturing refers to the use of advanced technologies to improve production. Think of it as combining software, robotics, and data analytics. This blend helps companies make better decisions, reduce waste, and enhance productivity.

Imagine a factory where machines communicate with each other. They share data in real-time to streamline production. This is smart manufacturing in action. it’s all about efficiency and responsiveness.

Why is Automation Important?

Automation plays a critical role in smart manufacturing. But why should we care? Here are some key reasons:

- Increased Efficiency: Machines can work 24/7 without breaks, leading to higher output.

- Cost Savings: Automating repetitive tasks lowers labor costs and reduces errors.

- Improved Quality: Consistent processes ensure products meet high standards every time.

- Enhanced Safety: Automation takes over dangerous tasks, protecting workers.

These benefits can lead to a significant competitive edge. A study by the National Association of Manufacturers found that companies embracing automation see a 30% increase in productivity. that’s impressive!

How Does Automation Work?

At it’s core, automation uses technology to perform tasks with minimal human intervention. Lets break it down:

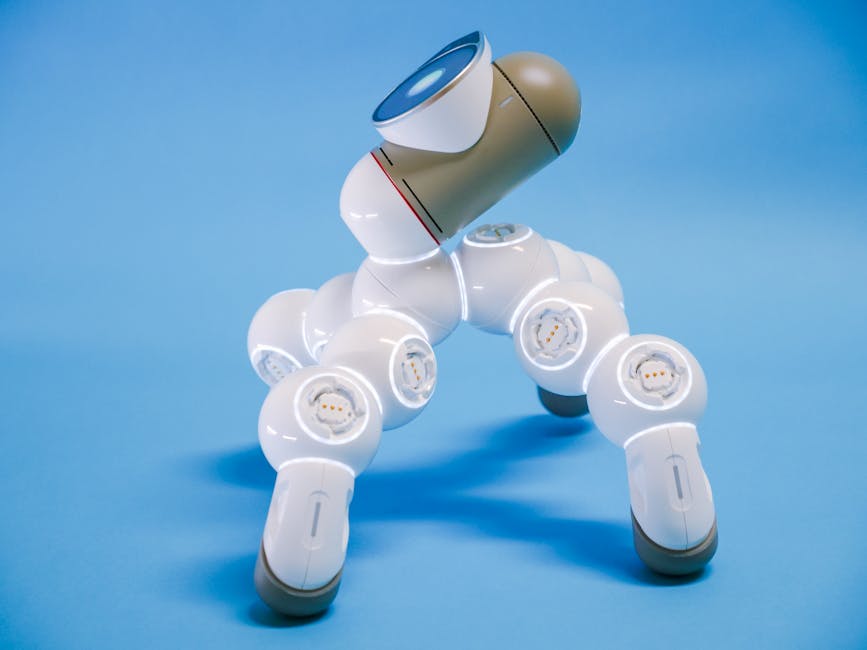

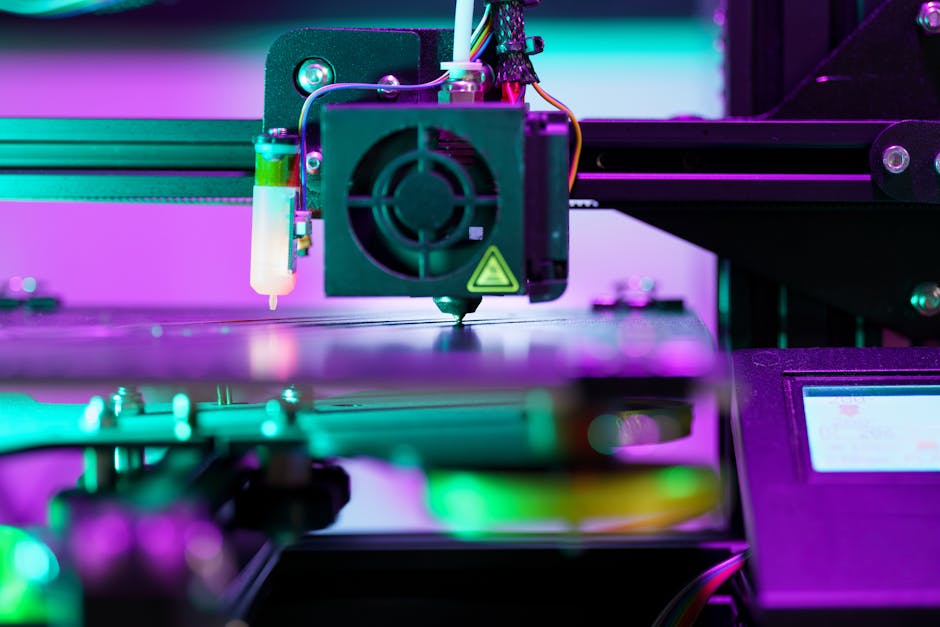

- Robotics: Robots can handle complex tasks like welding, painting, or assembly. They can work faster and more accurately than humans.

- Software: Programs can manage supply chains, track inventory, and analyze data to predict trends.

- Artificial Intelligence (AI): AI can learn from data and make decisions, optimizing production processes.

Think about a home thermostat. It learns your schedule and adjusts the temperature accordingly. Similarly, machines in factories can learn from their environment and optimize operations.

What Are the Benefits of Automation in Manufacturing?

Lets explore some specific benefits automation brings to the manufacturing world:

1. Greater Flexibility

Automation allows manufacturers to adapt quickly to changes. If demand spikes for a product, automated systems can ramp up production without needing extensive retraining of staff.

2. Data-Driven Decisions

Automated systems collect data all day long. This information helps managers make informed choices. For example, if a machine shows signs of wear, it can alert staff before it breaks down.

3. Better Customer Satisfaction

With improved quality and efficiency, customers receive products faster and at lower prices. Happy customers often lead to repeat business.

4. Sustainable Practices

Automation can help reduce waste and energy consumption. Machines can optimize the use of resources, leading to a smaller environmental footprint.

How Can Companies Implement Automation?

Companies looking to automate need a strategic approach. Here are some steps to consider:

- Assess Needs: Identify which processes can benefit from automation.

- Invest in Technology: Choose the right tools, whether it’s robotics, AI, or software.

- Train Employees: Ensure staff understand how to work alongside automated systems.

- Evaluate and Improve: Continuously monitor performance and adjust as needed.

By taking these steps, companies can seamlessly integrate automation into their existing workflows.

What Challenges Come with Automation?

Despite the benefits, automation isn’t without it’s challenges. Here are a few common concerns:

- High Initial Costs: Setting up automated systems can be expensive.

- Job Displacement: There are fears that automation will replace human workers.

- Technical Issues: Automation systems can fail, leading to production halts.

However, it’s essential to view these challenges as opportunities for growth. With careful planning and training, businesses can mitigate these risks.

What is the Future of Automation in Manufacturing?

The future looks bright for automation. Experts predict that as technology evolves, more manufacturers will adopt these practices. Heres what we can expect:

- Increased Collaboration: Humans and machines will work together more closely.

- Greater Customization: Automation will enable more personalized products for consumers.

- Smarter Factories: AI and machine learning will lead to even more efficient processes.

As a result, well see a shift towards more innovative and responsive manufacturing practices.

Conclusion: Embracing Automation in Manufacturing

Incorporating automation into manufacturing is no longer optional; it’s essential. Companies that embrace this technology will see enhanced efficiency, improved quality, and greater customer satisfaction.

Remember, automation is not just about replacing jobs; it’s about transforming them. Workers can shift from routine tasks to more strategic roles, adding value to their companies.

If you’re interested in learning more about smart manufacturing, check out this article on [Smart Manufacturing Trends](https://www.smartmanufacturing.com) to stay updated on the latest developments.

As we move forward, lets welcome automation as a partner in manufacturing, not just a tool. The future is bright, and it’s automated!